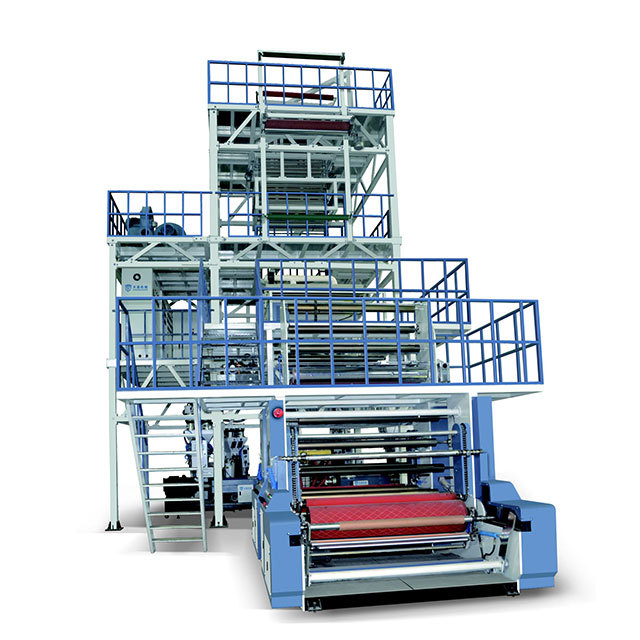

The new type of extrusion technology, production (production capacity more than 30%), while And good plasticizing properties.

The new technology center feeding spiral die, compact, quick-change Recipes, saving raw materials.

Horizontal rotary film traction system, greatly enhance the quality of the film roll, DU Flounced phenomenon must adapx to high-speed printing, complex treatment processes.

Emphasis on economic blown film equipment devices, high capacity and low power consumpxion, Good value for money, honesty is the ideal choice for our customers.

| Model | TS-GS1700 |

| Number of layers | 3 |

| Film folding diameter | 1600mm |

| membrane thickness | 0.03-0.12mm |

| maximum output | 250-300kg/h |

| Use raw materials | MLLDPE, LLDPE, LDPE, EVA |

| Screw diameter | ¢55-¢65-¢55 |

| Screw aspect ratio | 30:1 |

| Screw speed | 120r/min |

| Main motor power | 22/37/22kW |

| Bubble cooling mode | Precision double air outlet negative pressure air ring, IBC film bubble internal cooling system |

| Rotary traction form | Horizontal 360 degree, rotating traction system |

| Towing speed | 45-120min |

| Total power | 220kw |

| Overall dimensions (LxWxH) | 11000x7000x10000mm |

| Weight | 30T |